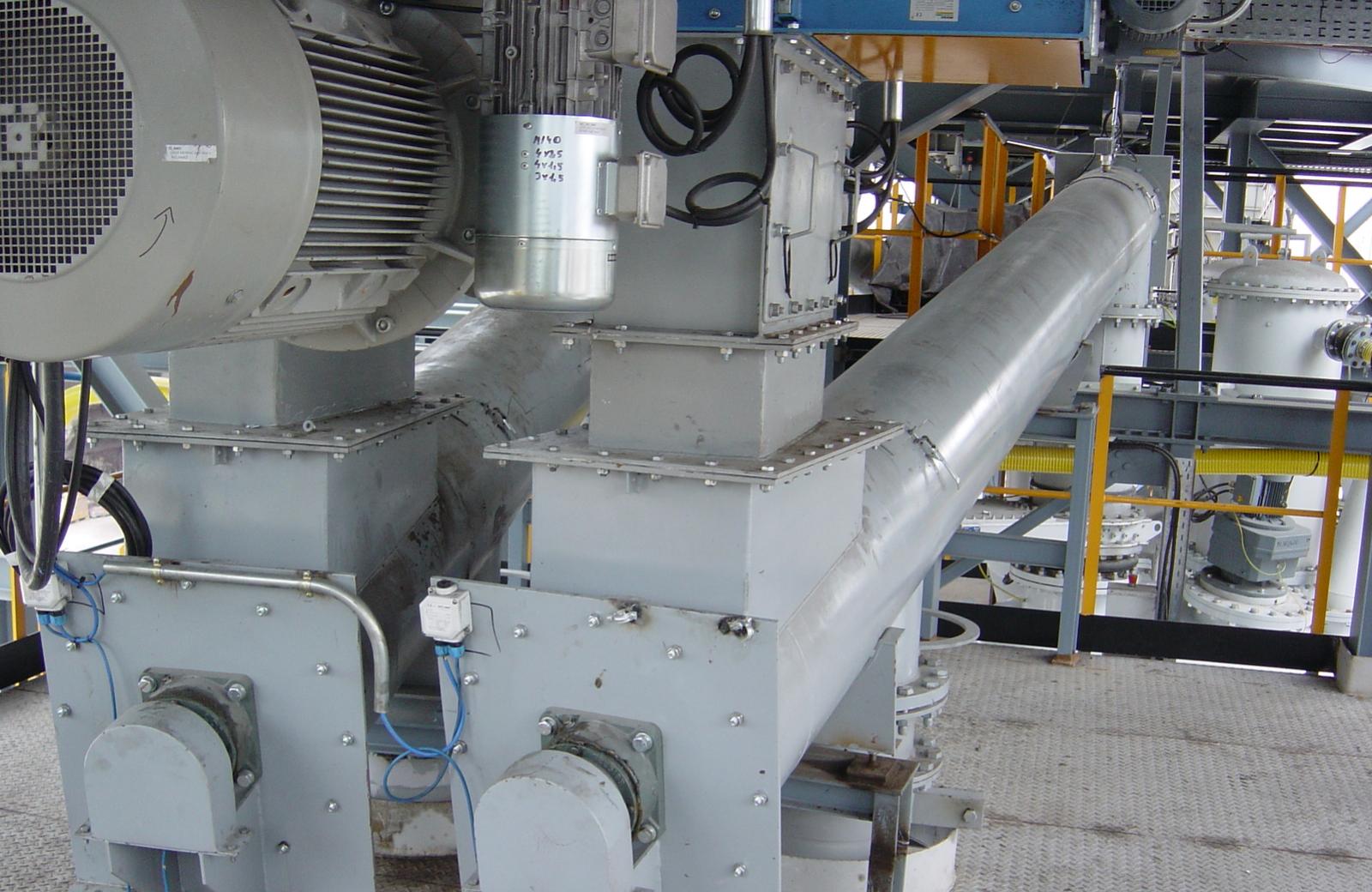

When it comes to bulk material handling equipment in industries like mining, aggregate, cement, gypsum, and power generation, efficiency, reliability, and long-term cost savings are paramount. One often overlooked factor that can significantly impact maintenance costs and downtime is the type of connection used in the structural components of the equipment. At WTW Americas, we recognize that the choice between bolted and welded connections can make all the difference. That’s why our systems feature bolted connections, offering a range of advantages over traditional welded designs.

The Problem with Welded Connections

Welded connections have long been the standard in bulk material handling equipment, but they come with inherent limitations. While they provide a strong bond, welded connections are fixed, rigid, and often more challenging to maintain over time. If equipment requires modification, repair, or replacement of parts, cutting through the welds is a labor-intensive and time-consuming process. This can lead to extended downtime, loss of productivity, and significant repair costs.

For industries that rely on constant production, such as mining or power generation, the cost of halting operations to fix equipment can be substantial. In the fast-paced environment of bulk material handling, where downtime can translate into losses in the thousands or even millions of dollars, minimizing these disruptions is critical.

The Bolted Connection Advantage

WTW Americas’ innovative approach to bulk material handling systems revolves around the use of bolted connections, providing flexibility, reduced downtime, and cost-effective maintenance.

1. Quick and Easy Repairs

Bolted connections make it far easier to disassemble equipment for repairs or maintenance. Instead of cutting through welds and re-welding after the repair, technicians can simply unbolt the affected part, perform the necessary work, and reassemble the equipment. This significantly reduces downtime, allowing production to resume much faster compared to welded systems.

2. Improved Flexibility

With bolted connections, the system becomes modular. This means individual components can be replaced or modified without disrupting the entire system. Whether it’s for repairs, upgrades, or expansions, bolted connections provide a level of flexibility that welded systems cannot match. This adaptability is crucial in industries where needs and demands often change, allowing for faster reconfiguration of systems to meet new operational requirements.

3. Enhanced Durability and Safety

While some might assume that bolted connections are weaker than welds, the reality is that modern bolting technology ensures these connections are incredibly strong and secure. Bolted systems are also less likely to experience the material fatigue or stress cracking that welded joints may suffer over time, particularly in high-vibration environments. As a result, bolted connections offer longer-lasting durability and contribute to the overall safety and reliability of the equipment.

4. Reduced Costs Over Time

The cost of maintenance and repairs can accumulate over the lifespan of any bulk material handling system. By opting for bolted connections, businesses can drastically reduce these expenses. The ease with which repairs can be made translates directly into lower labor costs, minimized downtime, and reduced need for expensive, specialized welding services.

A Commitment to Innovation

WTW Americas is committed to delivering equipment solutions that not only perform reliably but also offer tangible cost savings to our clients. The decision to use bolted connections across our bulk material handling systems reflects our dedication to innovation, efficiency, and customer-centric design. We understand that in industries where every hour of downtime matters, solutions that enhance uptime and simplify maintenance are invaluable.

Conclusion

When choosing bulk material handling systems, considering the type of connection—bolted versus welded—can have a profound impact on long-term costs and operational efficiency. WTW Americas’ bolted connection systems offer faster, more cost-effective repairs, greater flexibility, and improved safety and durability. This thoughtful design choice helps our clients minimize downtime, reduce maintenance costs, and keep their operations running smoothly, day in and day out.