Reliable Silo Discharge Machines

Descarga, distribuição, recuperação e armazenamento de materiais a granel

Os descarregadores de silo são empregados para materiais com características de fluxo tão ruins que a gravidade por si só não é suficiente para permitir que eles fluam de um silo, tremonha ou tanque. Essa solução de equipamento evita problemas típicos de descarregamento, como aderência, formação de pontes e ratholing.

About the Silo Discharge Machine

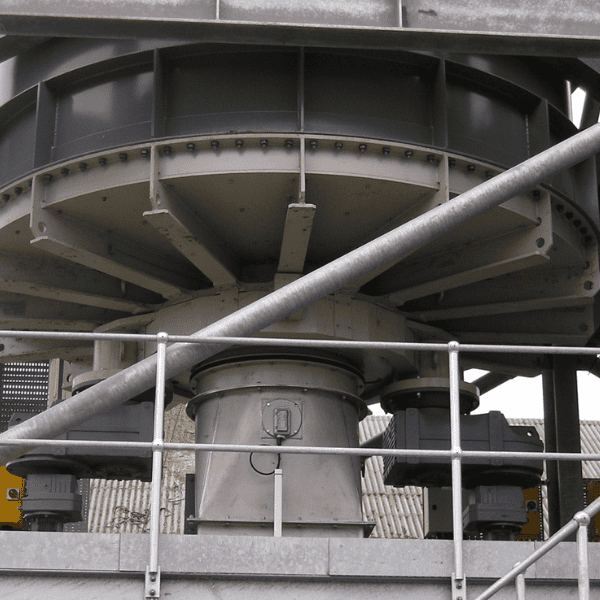

WTW’s Silo Bin Discharger is our most versatile and flexible discharge system. Available in sizes from 1.5 to 6 meters in diameter and discharge capacities up to 1,000 t/h, WTW’s Silo Discharge Machine is one of our most requested installations.

A tarefa da máquina de descarga de silos da unidade de descarga central é extrair materiais a granel úmidos, quentes, coesivos, lentos e outros materiais a granel de fluxo não livre armazenados ou armazenados em caixas ou silos.

O braço de descarga rotativo transporta o material a granel em direção à abertura no centro do piso e o descarrega por essa abertura. Para evitar que o material a granel flua para fora de forma descontrolada, a abertura de descarga é coberta por um cone interno. O braço de descarga passa por baixo do cone interno e ativa todo o fundo do silo durante a operação de descarga.

One revolution of this specially curved and profiled arm extracts a uniform disc of material from the silo. This keeps the bulk material column in motion and maintains its flow ability, preventing solidification of the bulk material over time and the risk of bridge formation and ratholing inside the silo.

Free Spinning Cone

The free spinning cone has the advantage of having no obstacles such as cross beams or cone supports that would disrupt the material flow. Very sticky or non-free flowing bulk materials have no chance to build bridges. This feature allows for a bulk material to have up to 3 times the amount of storage time at rest when compared with a cone supported by beams. This design should be used for wet bulk materials such as FGD Gypsum, Clay, Marl, etc.

Cone Supported by Beams

This design is used for bulk materials with poor flow characteristics, or for surge bins where long periods of storage time are not necessary. Typical bulk materials used in this machine are Limestone, Natural Gypsum, Ores, Coal, Petroleum Coke. Coarse or dry bulk materials can also be used with this machine.

Internal Drive

This feature gives you the advantage of storing very dusty bulk materials or materials that have the tendency for spontaneous combustion. One of the arms is built as an inspection tunnel, so drive maintenance can be done without emptying the silo. Typical applications are Pulverized Coal, Sub-Bituminous Coal (PRB coal), Wet Fly Ash and Land Plaster.

Benefícios para você

- Otimiza o espaço de armazenamento.

- Fornece descarga consistente e confiável do seu material.

- Continuous mass flow applicable to every industry.

- Heavy duty, reliable design minimizes downtime and maintenance.

The Silo Discharge Machine can be used in pits to efficiently empty rail cars or trucks, and in hoppers to unload clam shells or front-end loaders—or traditionally used in silos.

Saiba mais

To learn more about WTW Americas Silo Discharge Machine email info@wtwamericas.com ou ligue para +1705-749-3544.